Need to reduce your monthly ultra-pure acid bill?

Bring on-demand acid purification in-house!

Realize up to 90% cost savings by purifying low-cost reagent grade acids to create the ultra-high purity acids you need to lower ICP-MS detection limits.

The increasing demand for lower detection limits is a major consideration for any laboratory that is carrying out elemental determinations by ICP-OES and ICP-MS. The analytical instrument is just one component in achieving the lowest limits of detection. The other critical area that puts significant demands on a laboratory’s overall detection capability is to ensure that the sample preparation procedure does not contribute any additional sources of contamination. Several factors must be considered when looking to minimize contamination and reduce blank levels when preparing samples for analysis by plasma spectrochemistry. These include equipment cleanliness, reagent purity, quality of materials, and the digestion procedure itself.

| REAGENT PURITY

Currently, many laboratories purchase expensive high-purity acids for trace elemental analysis. There is, however, an alternative approach. Milestone has developed the duoPUR, a sub-boiling distillation system that allows laboratories to make their own high-purity acids at dramatically reduced costs. The advantages of the duoPUR include:

- Up to 90% cost savings by purifying low-cost reagent grade acids

- High productivity of up to 3 liters in eight hours

- Continuous supply of high-purity acids

- On-demand acid purification

- Re-purification of contaminated acids

- Single or double distillation

| PRINCIPLE OF OPERATION

Sub-boiling distillation is a technique based upon vaporizing a liquid by radiative heating of its surface to prevent boiling. It is recognized as the best method to obtain high-purity reagents typically used in ultra-trace analysis. In conventional distillation, violent boiling action generates aerosolized particles, resulting in re-contamination of the distillate by the original liquid. Surface evaporation during sub-boiling distillation prevents this, yielding a higher purity distillate.

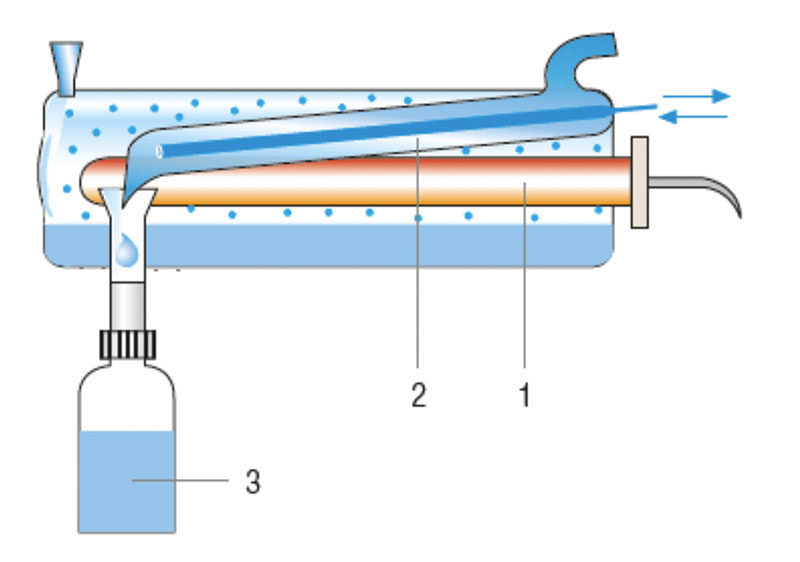

The duoPUR (Figure 1) consists of two high-purity quartz distillation units with two heating elements (1), a water-cooled condenser (2), reagent collection bottle (3), and a drain. The distillation process is microprocessor controlled, allowing the user to set the distillation time and power level. Infrared heating gently vaporizes the surface liquid, accelerating evaporation, and preventing aerosolized particles. Vaporized liquid is collected on an inclined cold finger where it condenses and drips into the high purity PFA collection bottle.

| COST SAVINGS

It’s also worth pointing out that there are significant cost savings when using the duoPUR, compared to purchasing high purity reagents. This is demonstrated in the following example (all costs are provided as estimates for example purposes only): If a laboratory processes 200 samples per month using 30 mL of ultra-pure nitric acid (J.T. Baker Ultrex II) per sample, it will use 6 L of ultra-pure acid at a cost of approximately $5,500 per month or $920 per liter per month. Six liters of reagent-grade acid (Sigma Aldrich) would only cost approximately $250 per month, or $40 per liter per month. By distilling this lower grade acid, $5,300 would be saved every month, which translates to the duoPUR paying for itself in less than four months.

By using the simple calculation, the cost savings for your lab can be estimated. Simply fill in your own information to calculate the potential monthly savings. CLICK BELOW.

Latest Articles

Check the sustainability of your methods now!

Maximizing laboratory flexibility with ETHOS Easy in environmental testing