Avoid downtimes with a period replacement of the PTFE liner

14 July 2023

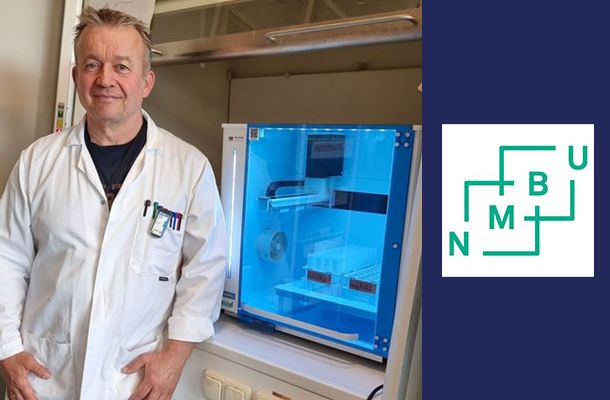

ultraWAVE uses high-pressure reactor that works at elevated pressure and temperature to simplify and expedite your digestion procedures. ultraWAVE relies on some crucial components to hold the pressure during the run and ensure proper operation.

| PERFORMANCE ALWAYS AT ITS BEST

The PTFE liner of ultraWAVE, particularly its bottom, is routinely exposed to high temperature and pressure, which creates high stress to the material. The design and the robustness of the PTFE liner enables safe and reliable operation over time. However, to handle these conditions, it has to be always at its best. It is crucial to routinely check the status of the liner bottom and to replace it if any damage or deformation is observed.

Be sure your lab has:

- Reliable runs

- Reduced downtimes

Latest Articles

ETHOS LEAN, ETHOS LEAN 2, ETHOS Platform, ETHOS UP/EASY, ultraWAVE 1 and 2, ultraWAVE 2 eco, ultraWAVE 3

Check the sustainability of your methods now!

The GreenPrep MW Score is a revolutionary tool designed by Milestone to help laboratories acro…

ETHOS LEAN, ETHOS LEAN 2, ETHOS Platform, ETHOS UP/EASY, ultraWAVE 1 and 2, ultraWAVE 2 eco, ultraWAVE 3

Optimizing Sample Preparation Workflows for Heavy Metals and Organic Pollutants in Environmental Labs

Comprehensive eBook that outlines best practices and technologies for improving efficiency, accurac…

ETHOS LEAN, ETHOS LEAN 2, ETHOS Platform, ETHOS UP/EASY, ultraWAVE 1 and 2, ultraWAVE 2 eco, ultraWAVE 3

Revolutionize Lab’s precision and safety with easyFILL automatic acid dosing system

The implementation of easyFILL brought measurable improvements to the lab’s operations, addressing…